| Added | Tue, 15/10/2019 |

| Sources | |

| Феномены | |

| Version type |

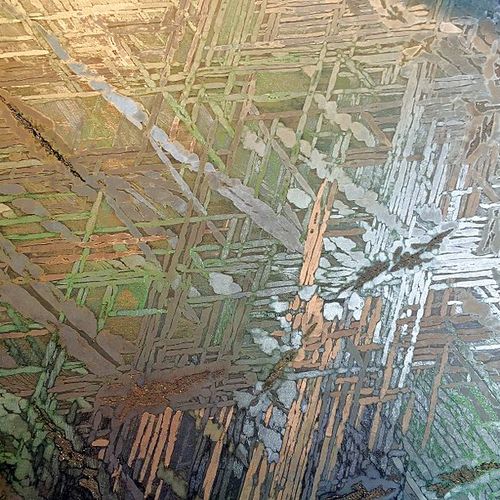

Widmanstatten structure or structure Thomson - a kind of metallographic structure of alloys in metallurgy and meteoritika, wherein the geometrically correct arrangement of the structure elements in the form of plates, polygons, or needles inside the components of the alloy crystal grains.

This term was used to refer to shapes or patterns occurs when the cut and etched with acid, most iron meteorites. Such a pattern arises, if at low temperatures of space two crystallizing mineral cannot be mixed. Attempts to create widmanstatten figures in laboratory conditions fail.

It looks like the structure of the iron meteorites (octahedrites), revealed by etching polished surfaces of the samples.

Widmanstatten shapes are formed by a system of parallel plates (beams): kamacite, regularly arranged parallel to the octahedron faces. Iron meteorites contain four such plates, the intersection of which with each other form a complex morphological pattern. Capacitive beams fringed with thin slices Tanita; the residual space between the beams is made of fine-grained mixture: kamacite and Tanita (plessite).

Appearance widmanstatten figures is primarily attributed to the extremely slow subsolidus cooling high-temperature originally homogeneous iron-Nickel phase. High-temperature face-centered modification of y-Fe, as well as poor Nickel it difference, when cooling it goes into a stable modification of a-Fe with body-centered lattice, whereas Ni-rich difference retain the face-centered lattice.

Significant Nickel content in the cooling system causes two-phase region, which expands with decreasing temperature; thus the a-phase precipitates mainly along the octahedral planes of the phases. Thus, the cooling process leads to disintegration of high-temperature Ni-Fe solid solution, which is the direct cause of widmanstatten figures.

Translated by «Yandex.Translator»

Log in or register to post comments